In the summer of 2020 we got in our goldsmith's studio a very unusual visit: The managing director of a medium-sized company and his wife even put up with a longer journey by car to see the replica of an originallate roman ring with layered agate from the end of the 3rd century.

Our customers had recently come into possession of this extraordinary antique gold ring through the art trade. However, since the ring is rather rare in this opulence and our customer liked the ring so much that she wanted to wear it on her own finger - but interfering with the historical substance was out of the question - both accepted our suggestion without further ado:

Instead, a true-to-the-original replica of the historic ring was to be made in a modern ring size that would fit our customer. In doing so, the defects in the original, which tend to hinder comfortable wearing, such as a broken ring band and a gemstone that is probably crooked due to a bump, should be corrected if possible. Otherwise, the attention to detail and the final patination should come as close as possible to the antique original.

Of course, we were very happy about this unusual order. It is rare to see such an elaborate and valuable original up close. So I was able to apply all my technical experience of historical goldsmith techniques and, for example, to the uncompromising patination. One feels strangely close and connected to the antique master goldsmiths. Wonderful.

The almost 1700-year-old original ring is made of almost 950/- yellow gold and has a particularly elaborate ring band made of corded and snake-shaped gold wires. In addition, the center of the ring is adorned with a ring set with leaf ornaments (?) and probably rarer and more typical of the time in its color distribution Layered Agate.

Inquiries with art historians from a state museum who specialize in Roman antiquity revealed that the ring could probably have come directly from the center of the then Roman Empire, if not from Rome itself the highest social circles.

Interestingly, we also found out that because of its tiny ring width, such a ring was perhaps not worn very low down on the finger in the way that is common today, but rather on or just behind the first finger joint – i.e. directly behind the fingertip.

Our special focus was initially on procuring a layered agate that was as similar as possible. Unfortunately, our efforts with several large suppliers in the gemstone town of Idar-Oberstein, with our gemstone cutter, on the worldwide Internet and with various other sources were unsuccessful. Apparently, the exact order, width and color of the natural agate layers lying on top of each other was too rare for a suitable mineral to be found on the market within an acceptable period of time.

After consultation with our two customers, we finally decided to commission a so-called layered agateTriplets” at our gem cutter. The result of his efforts finally left nothing to be desired:

Now it was time to melt the authentic gold alloy. Approx. 95% fine gold was alloyed with approx. 5% fine silver, ie bonded together by intense heating under a gas burner.

At around 1100 degrees, both metals finally melted into an alloy that corresponds to the ancient original. It's pretty martial: 😉

The starting precious metal obtained in this way could then be formed into the desired ring ornaments of the ring band and the gemstone setting for the layered agate. For this purpose, for example, a wide variety of wires were rolled out for the production of the ring band and then partially knotted together, i.e. twisted into each other:

Beforehand, the ring band was first made in fine silver as a test in order to determine the individual processing steps and the exact material thicknesses and to test their possible resilience in advance through the later soldering and stretching.

For example, the beaded wire was formed using a modern CD. However, it was probably different with the ancient Romans. 😉

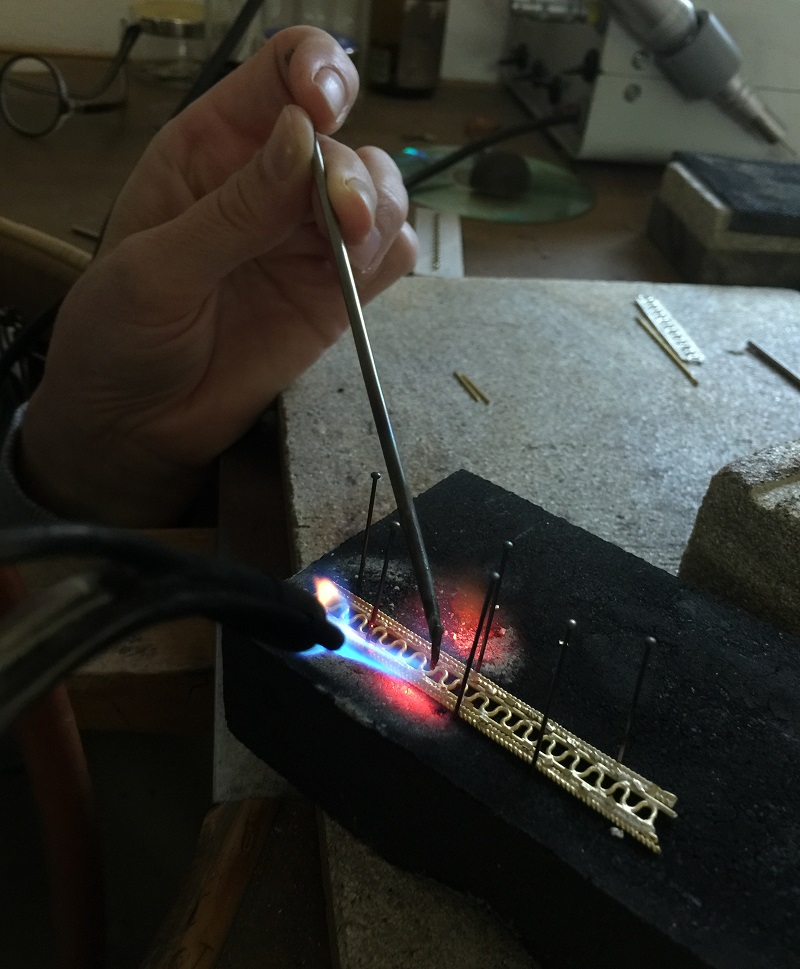

Now all the individual gold ornaments of the ring band could be soldered together.

Finally, the ring band and the ring head including the gemstone setting were connected and the beautiful layered agate could be set. After that, all components were painstakingly patinated again, ie the surface of the ring was matched to the antique original with regard to the signs of wear.

The enthusiasm of our two customers was written all over their faces. Apparently we were able to fully meet the expectations and therefore, after the ring was handed over, here in our studio we were full of inspiration and very happy about this rewarding and exciting order.